If you are looking at inflatable tents for sale or flirting with overlanding or just want a new camping tent for the family, you must have come across something like ‘150D 320gsm Oxford Poly Cotton HH 6000mm’. Did you ever wonder what is the difference between tent fabric types? What is hydrostatic head, if you ever heard of it? Why is there a PU coating, what is a PU coating anyways?

Denier, thread count, gram per square inch, hydrostatic head…hmmm…

Lately it has become something we have seen before with personal computers, RAM memories, mobile phones, cameras or TVs: a lot of technical staff, NUMBERS most of all, thrown at you and OBVIOUSLY the bigger the better, right?

Well, not so much, when it comes to selecting tent fabric. Each tent fabric type has different qualities, good and bad points. Picking the right mostly depends on your NEEDS, the way you would use your tent, its purpose.

You probably have heard of many different types of tent fabric from polyester to poly-cotton, not to mention the different brand names like OutTex or Protex or Sentinel, just to mention a few. Of course, they all claim they are better than the others, but the fact that you don’t even know what’s behind the catchy brand names, does not help.

JUMP RIGHT TO THE COMPARISON TABLE!

Search for the brand name / manufacturer and find out the specs for the flysheet fabric.

Tent Fabric Comparison Chart – You can search / filter, works best on larger screens

Perhaps you also noticed that there are more expensive and there are less expensive fabrics, but the fact that one is more expensive does not make it BETTER, if it is not FIT FOR THE PURPOSE you need it for.

Tent Fabrics Types – What is the difference?

400D Oxford fabric

So each tent fabric has good and bad points. For example, you may need a lightweight tent that is easy to carry, or you need one that you set up in the June and you won’t touch it till September, even in the poorest weather? Or you need something that dries quickly so you can leave the camp as early in the morning as possible?

The vast majority of tents are made of nylon or polyester. Here on 10ts-tents you mostly find polyester and poly-cotton tents, as nylon is more often used for lightweight backpacking tents, and not so much for large(r) and heavy(ier) family tents or roof top tents.

Polyester tent fabric

Polyester is a popular choice, because it is cheap, and it performs well in various weather conditions. Polyester is the most common fabric used in tents. Although it is not waterproof (unless coated), it doesn’t change shape when wet (unlike nylon) and does not perform too bad in sunlight. It is also more durable than nylon, and despite it is heavier, it is not too heavy and packs down fairly small. Polyester is also relatively quick to dry out and has natural resistance to mildew and rips.

On the flipside of the coin, especially if compared to the, THE, traditional tent fabric the cotton, polyester is not a good insulator. This means that polyester tents can get very hot when it is warm, and chilly when it gets cold. Also, especially when a coating has been applied, it is not breathable, which can lead to condensation building up inside.

Also bear in mind that they can lose colour over time through exposure to sunlight, and the fabric weakens to as the UV rays break down the molecules.

Pros: less maintenance, strength, stretch and tear resistance, not too heavy, affordable, packs down small, good mildew resistance, waterproof

Cons: Not great UV resistance, bad insulator, low breathability causing condensation, limited lifespan

Cotton / Canvas tent fabric

Cotton or canvas is the original, the one, the tent fabric your grandad probably used. A long time ago canvas was made from hemp, but nowadays tent canvas is made from cotton. Manufacturers tend to use both which can be confusing, but the two – cotton and canvas – are the same thing.

Cotton is thick, durable and breathable, and is naturally waterproof, does not need any coating. As water starts soaking the fabric, the fibres expand and swell, sealing off the gaps between the threads. It may leak the first time in rain as the swelling process takes time, so it is a good advice to weather/season the cotton tent before using it for the 1st time.

Cotton also has very good thermal properties, it is an extremely good insulator. The tent will remain cool in the summer, and stays warm if the weather turns cooler.

As it is naturally breathable and absorbs water, you won’t have any issues with condensation.

It is thick and heavy, which not only makes it a good thermal insulator, but it is a very good acoustic insulator as well: it is quieter, you are not going hear the lightest breeze flapping the thin fabric like on a polyester tent.

On the negative side, cotton is heavy and bulky. It is not easy to carry due to its weight, and you must doublecheck if it fits into the boot of your car. Pitching needs more effort too.

It also requires more maintenance. You need to dry the material out before putting the tent away, otherwise you will get mildew in the tent. And drying it out can take much longer than any polyester tent, as cotton absorbs water.

Cotton, as a natural fabric, rips much easier, which can turn into a huge tear very easily.

Lastly, cotton tents are not cheap.

Pros: breathable, naturally waterproof, less condensation, good insulation, long lifespan, high UV resistance

Cons: expensive, heavy, bulky, prone to mildew, can’t be used out of the box, requires maintenance, needs to dry out before packing away

Polycotton tent fabric

Poly-cotton is a blend of cotton and polyester. While keeping all the good qualities of cotton, it has some of the benefits of polyester tents. The main fabric is cotton, with polyester in the weaves, so it inherited some of the mildew-resistance, it is stronger and less likely to rip than pure cotton. Poly-cotton can be left uncoated but usually there is a coating applied to repel water.

Its durability, breathability and weather resistance make it great for family camping tents, swags and roof top tents.

Pros: better strength and mildew resistance than cotton, better resistance to UV and heat than polyester, breathable, less moisture and condensation, longer lifespan and better weight than cotton canvas

Cons: cost, still heavy and bulky, less mildew resistance than polyester

Oxford fabric

Oxford is a different type of weave which provides better strength and durability. You probably won’t come across a polyester Oxford fabric ever. What you may come across though is Poly-Oxford, which refers to poly-cotton or technical cotton; or Oxford cotton, which normally is polycotton again but you’ll never know. It is one of those sloppy use of words that make more confusion than actually describing what the fabric is made of. It can be cotton, it can be polycotton, you’ll have to ask the seller or make your own guess based on the price.

What’s the difference between the Oxford and non-Oxford fabric? Oxford weaving is also called ‘basket weave’. The fabric normally feels a bit rougher than the non-oxford cotton or poly-cotton, owing to the tw0-by-two weaving. It does not affect the original properties of the material the weaves are made of: it’s waterproof etc., but the special weaving increases its strength and durability.

Often used on tents because tent makers can reach the required strength of the fabric while it remains noticeably lighter than a no-oxford-weaved fabric.

Oxford weaving

Brand specific tent fabrics

Some tent companies brand their mix of tent fabrics, treatments, and coatings. This does not help in understanding the properties of the tent fabric, and ultimately it feels like I am being sold something that I don’t know anything about.

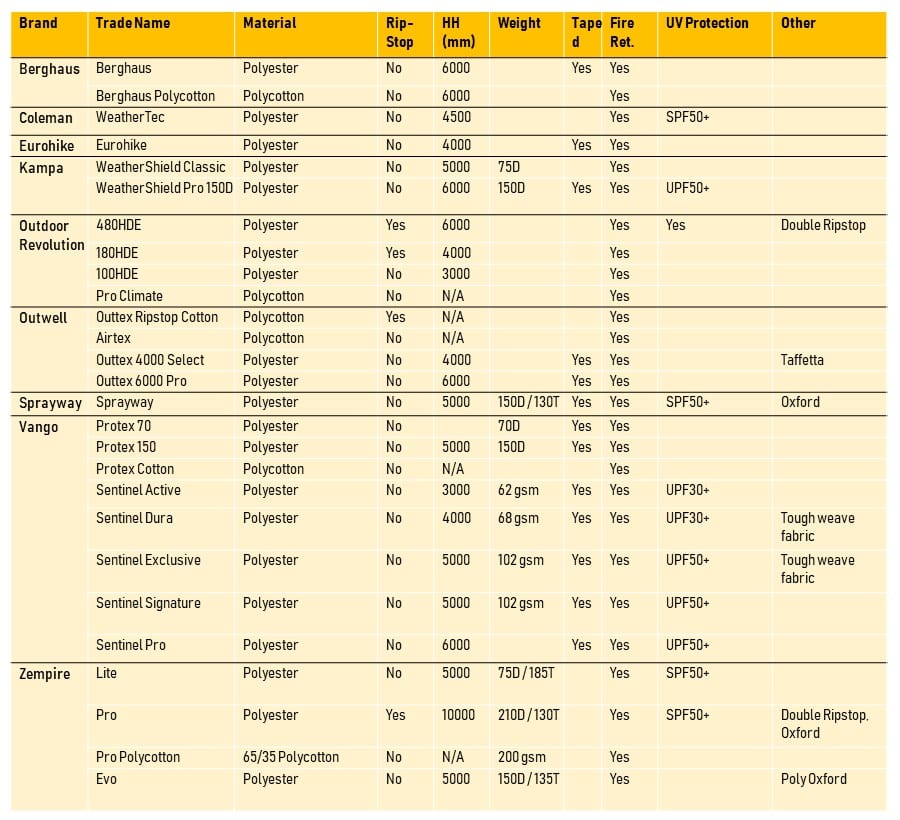

The table below doesn’t list every brand specific tent fabric, but I have tried to cover all that have been mentioned on the site before:

Tent fabrics / materials and their main features

So which is the best tent fabric?

As I said at the beginning, it depends a lot on the purpose. When I write a review of an inflatable tent or a roof top tent, and I ask the question ‘who is it for?’; I always look at the fabric material first. Poly-cotton tents provide you with a much relaxed, home-to-home feeling thanks to their better thermal properties, making them ideal as a family tent. But due to their weight, I would not necessarily recommend them for a quick weekend-break; a polyester tent would fit that purpose a bit better. Each fabric has good properties and bad ones, and I cannot emphasise enough how important it is for you to know, how you will use the tent.

So for families, if you can afford, transport, and pitch it; go for canvas / cotton, or poly-cotton. The latter one, ie the pitching part, can be beaten easily if you go for an inflatable poly-cotton tent. If you camp in cooler weather ie outside the summer holidays, I would strongly recommend cotton or poly-cotton tents.

Otherwise, a polyester or nylon tent would certainly do a good job. If it gets too hot, just open the vents and make sure that you have as many mesh doors as possible, so you can let the fresh air in and keep the bugs out during the night.

Tent Fabric Specifications – What do they mean?

Denier

Denier (D) is the unit measuring the weight and thickness of the individual threads used in the fabric. The higher the Denier; the thicker, stronger and heavier the fabric. You must also count in the different types of fabrics as they have different strengths. A stronger fabric such as nylon normally needs less Denier to produce a strong and durable tent AND keep the weight as low as possible. So you will find lower Denier in ultralight tents and tarps.

Camping tents typically use higher Denier polyester fabric, most common values are 68D, 70D, 75D.

Camping tents with 150D or more are ideal for longer exposure to the sun and inclement weather. Apart from a few examples of 150D camping tents, this type of fabric is more typical in event shelters where it needs to endure more stress.

Rooftop tents are different beasts, and it is not uncommon to see 320-400D fabrics on them.

Thread count

The thread count (T) represents the number of threads used per square inch of fabric. 190T for example means that 190 threads were used horizontally and vertically per every square inch. This also means that the thicker the thread is (higher Denier), the lower the thread count will be.

A higher thread count means a greater density in the fabric, so you will most likely find higher thread counts with lower Denier fabrics. But don’t fall for the numbers.

High thread counts can certainly make for better sheets of fabric, but it’s the thread itself, that matters most. In fact, a fabric of a better-quality fibre with a lower thread count will feel ‘softer’ and better-made than a fabric of a lower-quality fibre with a higher thread count.

So, a higher thread count doesn’t mean a stronger fabric, it depends on the quality and thickness of the fibre used. Actually, if nothing else is known about the flysheet or the groundsheet than the thread count (and it is intended to sound GOOD), I would become suspicious…

GSM

In simple terms it means the weight of the fabric, GSM refers to grams per square meter. But fabric weight is usually a definition of the thickness of the garment itself, but it is not always as simple as higher gsm means a heavier, thicker fabric.

You must also bear in mind that the weight does not tell you what type of fibre thread is used and how dense the thread count is. Fabrics with different fibres or weaves but with the same weight may not have the exact same thickness.

Also important to bear in mind that the weight of a material does not always determine its quality. Different fabric weaves will be different weights which is essential for its end use. While most tents range from around 280gsm to 380gsm, you will find the ‘high-end’ modern polycotton tents on the lower end of this range.

So, most of the time, the higher the GSM the stronger and heavier the canvas will be; but don’t compare apples to oranges…

RipStop

Ripstop fabric is a thin, lightweight and waterproof material, made of a combination of different fabrics. During weaving, a stronger thread – usually nylon or polyester – is added at regular intervals, which forms a distinctive rectangular pattern. This reinforcement makes any rips and tears less likely to spread, which makes it ideal for using it in outdoors equipment, including tents and others such as waterproof jackets, bags etc.

600D polycotton canvas

While it is a high-quality, breathable material, the name RipStop is a bit misleading though…You see it everywhere, more often on expensive outdoors equipment and it is certainly a special feature on some mid- to high-range tents. But what does it mean exactly? Well, it certainly does not mean that the fabric won’t ever rip.

So, bear in mind when buying tents, that ripstop will limit the damage, but the tent won’t become miraculously ‘rip-proof’.

Still not clear?

What makes it even more confusing, is that tent manufacturers tend NOT TO disclose all the specs of the tent fabric they use. This virtually makes it impossible to compare two different fabrics. For example: tent A has a 150D polyester flysheet, tent B has a 320gsm polyester flysheet, while tent C has a 75D 220T flysheet. Those metrics don’t convert to each other, the 75D fabric could easily have a greater density of the thinner thread, thus making it even heavier than the 150D fabric. While the 320gsm does not tell anything about the quality, the density or the thickness of the threads…

What are the different tent fabric coatings?

Depending on the tent fabric, different chemical coatings can be applied to increase their performance, mostly their resistance to water and UV light.

Polyurethane / PU coating

The PU coating is used to make the tent fabric waterproof. It can be applied to polyester and nylon fabrics, creating a waterproof layer. It is affordable and has good breathability. It does not permeate the fabric, but it is more like a layer that sticks onto the surface, hence it allows the application of tape on the seams. Depending on the type of chemical used and the number of layers applied, it determines the Hydrostatic Head millimetre rating (see further below) of the tent.

On the downside it requires care to be kept clean and dry for storage. Another drawback that UV exposure breaks down the chemical bonds over time, thus reducing the weather-resilience of the tent through its life-span.

What you need to consider, that it DOES limit the breathability of the polyester or nylon fabric, so the thicker the PU coating the less breathable the fabric remains. It also means increased weight, increased costs, and the chemicals in the coating can also weaken the fabric.

Also, the quality of the coating can vary from manufacturer to manufacturer; which can ultimately determine how long you will be able to enjoy your camping without rainwater leaking through the flysheet…

Silicon coating (a.k.a silnylon)

Nylon – just like polyester – is not waterproof. Instead of a PU coating, you may find that a silicone coating is applied to a nylon fabric, which is called sil-nylon.

The silicon coating goes in between the nylon fabric threads, so on the plus side it reinforces the nylon fabric, making it more durable, as well as making it waterproof. Silicone repels water, so you can easily sweep the droplets off the silnylon surface. It dries much quicker as well.

On the flipside, silicone coatings are not cheap, and since they fill in the gaps between the threads of the fabric, air cannot get through either. The lack of breathing in the fabric means that condensation can build up quickly and it turns the surface of fabric very slippery.

Silnylon tent seams cannot be taped, as they won’t stick to the slick surface. The seams need to be sealed by hand, using a liquid seam sealant. To get around this, manufacturers may apply a silicone coating on the outside and a PU coating on the inner side, this is called the SIL/PU coating.

Other coatings (UPF, SPF etc.)

There are various other coatings that can be applied to tent fabrics. Most notables are the ones that give fire retardant properties, and the ones that increase UV resistance. UV resistance is also important to protect the PU coating from breaking down over time, so in effect the UV coating can contribute to the overall water-resistance of the tent.

Ultraviolet Protection Factor (UPF) indicates how much UV radiation (both UVB and UVA) a fabric allows to reach your skin. For example, a UPF 50 fabric blocks 98 percent of the sun’s rays and allows two percent (1/50th) to penetrate, thus reducing your exposure risk significantly.

What you need to know: A fabric must have a UPF of 30 to qualify for The Skin Cancer Foundation’s Seal of Recommendation. A UPF of 30 to 49 offers very good protection, while UPF 50+ rates as excellent.

Be careful, as some manufacturers (Coleman) display SPF only for UV protection, rather than UPF: UPF measures both UVB and UVA rays, while SPF measures only UVB.

Hydrostatic Head (HH)

Hydrostatic Head (HH) measurement shows how waterproof a fabric is. The measurement gives a reading in millimetres: this is the maximum height of the column of water standing on the fabric before the water would penetrate the fabric.

According to Ultralight Outdoor Gear, the test used to be carried out using a physical column of water, but as fabrics have developed, the ratings were getting too high for this method. Nowadays the test is done using a machine that replicates the downward pressure that a water column of such height would create. The machine increases the pressure of water that is pushed against the fabric until water is visible on the other side. The required level of pressure used to force water through the fabric is then converted into a measurement of how high the water column would have been. This provides the result of the Hydrostatic Head test in millimetres.

Most tents discussed here on 10ts-tents have at least 1500mm HH or (waaay) above. Generally, a 1000mm HH means that the tent is ‘shower-proof’. You can find this rating on cheap pop-up tents, beach tents etc. Heavy rain and wind would create greater pressure on the fabric, so it needs at least 1500-2000mm HH in order to be considered ‘water-proof’. Anything beyond 2000mm HH means that the tent will keep out water even it is being pushed through by something physical, ie vegetation rubbing against it, or a person or backpacks / gear leaning on it.

A groundsheet needs to have a higher HH figure around 3000mm or higher ideally, as the pressure on material can be quite intensive when you sit, sleep, or walk on it.

Canvas fabrics don’t have a HH rating as they have a different way to keep the water out (see above). However, there are some manufacturers who apply a light waterproofing treatment on their tent. This allows for a quicker drying time, and the cotton remains breathable too.

There is one thing that you must bear in mind – again – that the HH rating rates the fabric, not the water-proof qualities of the whole tent. There are many other ways rainwater can get inside the tent (zippers, seams, vents, lack of canopies etc.) so the overall weather-resistance of the tent depends on a lot of other factors.

That’s why you just simply cannot to say that a 6000mm HH tent is more waterproof than a 2000mm HH one. It is about the fabric. Not the tent.

There is one company as an exception: Quechua. They don’t (always) tell the HH rating of their tents (but when they do, it is 2000mm HH). On the other hand, they put their tents through rigorous testing to simulate horrible weather conditions (heavy storms, wind tunnel) and they measure the overall weather-resistance of their tents. It is impressive and very convincing, and I like this approach very much.

Finally

Not sure I have made it clearer for you, or you just have more questions. But I do hope that from now on you will be able to narrow down the vast choice of tents to the ones that you actually NEED.

If you still have questions, don’t hesitate to drop me a line (contact details at the bottom of the page) or leave a comment!

Tent Fabric / Tent Material Comparison Chart

Inflatable Tents - Fabrics and materials

| Brand | Trade Name | Material | RipStop | HH | Weight | Taped | Fire Retardant | UV protection | Other | Products |

|---|---|---|---|---|---|---|---|---|---|---|

| Berghaus | Berghaus | Polyester | No | 6000 | Yes | Yes | Berghaus Air 4, Air 6, Air 4 XL, Air 6 XL | |||

| Berghaus | Berghaus Polycotton | 65/35 Polycotton | No | 6000 | Yes | Berghaus Air 6 Polycotton | ||||

| Coleman | WeatherTec | Polyester | No | 4500 | Yes | Yes | SPF50+ | Coleman FastPitch Air Valdes | ||

| Eurohike | Eurohike | Polyester | No | 4000 | Yes | Yes | Eurohike Air 400 | |||

| Kampa | WeatherShield Classic | Polyester | No | 5000 | 75D | Yes | Yes | Kampa Brean 4 | ||

| Kampa | WeatherShield Pro 150D | Polyester | No | 6000 | 150D | Yes | Yes | UPF50+ | ||

| Outdoor Revolution | 480HDE | Polyester | Yes | 6000 | Yes | Yes | Yes | Double Ripstop | Oxygen Ozone 6.0 XTR | |

| Outdoor Revolution | 180HDE | Polyester | Yes | 4000 | Yes | Yes | Airedale | |||

| Outdoor Revolution | 100HDE | Polyester | No | 3000 | Yes | Yes | Cruiz | |||

| Outdoor Revolution | Pro Climate | Polycotton | No | N/A | Yes | |||||

| Outwell | Outtex Ripstop Cotton | Polycotton | Yes | N/A | Yes | |||||

| Outwell | Airtex | Polycotton | No | N/A | Yes | Yes | ||||

| Outwell | Outtex 4000 Select | Polyester | No | 4000 | Yes | Yes | Taffetta | Reddick 4A | ||

| Outwell | Outtex 6000 Pro | Polyester | No | 6000 | Yes | Yes | Outwell Roseville, Lakeville, Airville | |||

| Quechua | Quechua | Polyester | No | 2000 | Yes | UPF30+ | ||||

| Sprayway | Sprayway | Polyester | No | 5000 | 150D / 130T | Yes | Yes | SPF50+ | Oxford | Sprayway Air Valley M |

| Vango | Protex 70 | Polyester | No | 70D | Yes | Yes | ||||

| Vango | Protex 150 | Polyester | No | 5000 | 150D | Yes | Yes | |||

| Vango | Protex Cotton | Polycotton | No | N/A | Yes | |||||

| Vango | Sentinel Active | Polyester | No | 3000 | 62 g/m2 | Yes | Yes | UPF30+ | Vango Airbeam Experience range | |

| Vango | Sentinel Dura | Polyester | No | 4000 | 68 g/m2 | Yes | Yes | UPF30+ | Tough weave fabric | Vango Airbeam Excel range |

| Vango | Sentinel Exclusive | Polyester | No | 5000 | 102 g/m2 | Yes | Yes | UPF50+ | Tough weave fabric | Vango Airbeam Elite range |

| Vango | Sentinel Signature | Polyester | No | 5000 | 102 g/m2 | Yes | Yes | UPF50+ | Vango Airbeam Elite range | |

| Vango | Sentinel Pro | Polyester | No | 6000 | Yes | Yes | UPF50+ | Anantara II Air 650 XL | ||

| Zempire | Lite | Polyester | No | 5000 | 75D / 185T | Yes | SPF50+ | Zempire Aero TM Lite, TL Lite | ||

| Zempire | Pro | Polyester | Yes | 10000 | 210D / 130T | Yes | SPF50+ | Double Ripstop, Oxford | ||

| Zempire | Pro Polycotton | 65/35 Polycotton | No | N/A | 200gsm | Yes | ||||

| Zempire | Evo | Polyester | No | 5000 | 150D / 135T | Yes | Poly Oxford | |||

Very helpful when deciding which seam sealant type to choose. A list of tent makers v. PU/SI waterproofing would be even better.

Hi Peter,

Good point, I shall update this post. I hope you have found what you were looking for, though.

Regards,

G

Hi Peter Casey! I live in California USA and am wanting to sew my own large poly cotton screen tent but cannot locate where to purchase the fabric. Do you know any sources? Also, is the best blend 85 percent cotton/15 percent polyester? Or is it the other way around…85 percent polyester/15 percent cotton? Also, is oxford the best for this application? And do the poly cotton tent fabrics come with a rain proof coating? Thank you for your kind help! Have a wonderful weekend!

what is the best fabric for manufacture off roof top tents , we curently using ripstop

Hi Shaun,

I am far from being an expert on fabrics, yet alone telling you what’s best.

Most manufacturers go for polycotton, because this fabric has best of both cotton and polyester (in terms of waterproofing, thermal insulation, durability etc.). Oxford weaving is more common in my experience than ripstop – Oxford weaving increases durability so you can use a thinner fabric to get the same strength (thus reducing weight).

Depending on the climate, you can use thinner or thicker fabric, that varies across the board.

Having said that, some roof tent makers go for polyester with reflective fibres weaved into the fabric (eg. James Baroud), which can be okay too (polyester is much lighter, so they can use more of it, ie bigger and lighter tents) but there are also a lot of comments on unusual wear on the JB tent fabric.

Others go for a thinner polycotton with a detachable polyester flysheet which is only used when the campers need protection from rain, and it dries faster than polycotton.

A lot depends on the quality of the actual coating too: while a lot of makers go for a higher HH proving, in my opinion a good UV protective layer that protects the fabric and the waterproof PU coating is must. It extends both the lifetime of the fabric and the waterproof coating (which the UV rays could break down over the years).

Hope this helps.

Greg

Thanks for your information. Helps understand the terrain!

I’m looking to replace the flysheet on my RTT as its deteriorating. The spec indicates ..oxford polyester flysheet with excellent water shedding ability – 1000mm/3ft water head..

I’d like to replace with something a little bit stronger and sew (normal sewing machine) with a new design and ensure its waterproof (happy to put on Fabsil or other waterproofing). What do you suggest (as lots of options out there with gsm,D,T etc.) thats not silly money.

Hi, your information is truly helpful.

I’m planning to make a simple sheet awning with poles to slide into the awning rail on our non-standard design caravan. Around 2.5m – 3m fastened to van, extending by 2.5 or so. Occasional use, and to be taken down in rough weather.

But I’m still unsure as to the best material and weight to use! Polycotton is tempting…

Also wondering whether Ripstop would be a good thing.

Any suggestions gratefully received.

With thanks.

Hi Richard,

I am far from being an expert but I think you are on the right path. Polycotton will less likely feel like you’re in a greenhouse when sitting under the awning, although it is slightly heavier than 100% polyester and takes slightly longer to dry out if caught by rain.

Ripstop is a good idea. If you can find ‘Oxford’ weaving, even better – lighter but more durable. What gsm fabrics are you looking at? Also, be careful cause most fabrics you buy might not have UV coating and might not be fire retardant.

You might have found a supplier with plenty of choice, I have found this however I don’t know what size of sheet they are able supply…

https://www.xmtextiles.com/

Hi Greg, Thank you for taking time to answer. That’s interesting, I’d only been hunting under tent fabric suppliers as such.

Because I’ve never made an awning before I honestly am feeling my way on weight. Something strong enough to work in that c. 2.5m square if the wind does suddenly gust, preferably not hugely heavy and bulky to pack, so a compromise!

I was guessing I’d probably need a central seam anyway, which gives more flexibility over supplies available.

If I go for polycotton, or Oxford fabric, in the range 8-11oz/ 3-400gsm, would you expect that to be up to it without being excessive?

And I was guessing that if it’s high in cotton it might not need UV coating, unlike thinner synthetic.

Thanks again,

Richard

Hi Richard,

If you can find polycotton or oxford fabric, I think 300gsm should be enough weight (order a sample if you can).

If you google ‘awning replacement fabric’ will probably return many results. It might be slightly different to what you are after, as these awning fabrics I found are 100% polyester or acrylic. On the other hand they are coated with water-, mould- and UV resistant and have great colour-fastness.

I also found heavy duty 600D, 20oz polyester fabric on Amazon, but that might be a bit over the top.- https://amzn.to/3kI3RCU

to be honest with you I’ve never built an awning before either so I’m not sure how much of help I can be

I was really hoping, especially after the in depth explanations given for polyester, cotton and polycotton, that you might explain Oxford fabric a bit more.

Instead, I am just as clueless now as I was when I clicked on the link to bring me here!

Is it cotton? Is it polyester? Is it a combination of the two? Is it always the same or is it sometimes one and not the other?

When you say “It provides better strength and durability…” Compared to what? Better strength and durability than cotton? Than polyester? Than plastic bin bag? Stronger and more durable than what???

As i treating as this article was, I clicked here with the sole purpose of finding out what Oxford fabric is, whether it is a type of polycotton and which of the two is better and I’m still just as oblivious so this article was a complete waste of my time. Disappointing.

Hi Vincent,

You actually answered your own question, but I’ve updated the section on Oxford fabric. Apparently it needed more explanation.

As I said in the post it is a different type of weaving (which also means it has nothing to do with material a fabric is made of). It can be polycotton or cotton, and when I say it provides better strength and durability it is compared to a non-oxford polycotton or cotton fabric, and a plastic bin bag too.

Hope this answers all your questions.

I found it interesting when you talked about tents and their different fabrics. Recently, my cousin said he’s interested in designing his own tent. My cousin loves do-it-yourself projects, so I think your guide will definitely help him! Thanks for the information on how to select a tent material that fits your special needs.

Thanks for you comment, Eli

would it be harmful to put canopy with 210 denier canopy fabric in the bedroom? I mean would the chemical effect the health of people?

Hi Peter Casey! I live in California USA and am wanting to sew my own large poly cotton screen tent but cannot locate where to purchase the fabric. Do you know any sources? Also, is the best blend 85 percent cotton/15 percent polyester? Or is it the other way around…85 percent polyester/15 percent cotton? Also, is oxford the best for this application? And do the poly cotton tent fabrics come with a rain proof coating? Thank you for your kind help! Have a wonderful weekend!

wondering if you are still providing comments/advice…. anout the use of different fabrics on tents, i am trying to figure out what to use on my tent to best insulate it(for warmth), thanks ! please just let me know if you are still available

I was looking at buying a tarp to primarily use as a footprint/groundsheet to protect the bottom of my tent (and potentially other uses as required). I’ve found two tarps; the difference between them is one is 190T Polyester Taffeta and the other is 210D rip-stop Oxford fabric.

I’m interested to compare the different properties for durability (especially as a groundsheet), breathability and waterpoofness.

There may not be much between them but any advice welcome 🙂